How to Maintain U-Values Without Sacrificing Function

Thermal performance matters, but so does usability. There’s no sense in having an energy-efficient building if day-to-day functionality is compromised. That’s the challenge: how do you keep low U-values without cutting corners on what the space actually needs to do?

Nowhere is this balance more obvious than when it comes to elements like roof access hatches. These components are often seen as minor details, but they can have a big impact on insulation, air tightness, and overall energy performance. Yet removing them or downgrading functionality isn’t a realistic solution. So the goal becomes smarter specification, not compromise.

Table of Content

Thermally Broken Roof Access Hatches: A Must, Not a Luxury

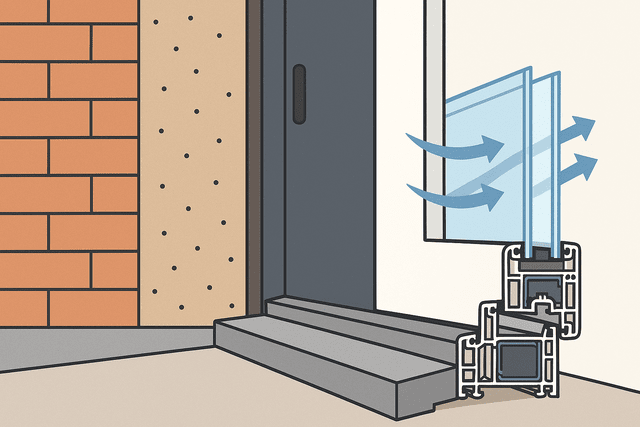

If you’re trying to hit low U-values across your building envelope, standard roof hatches just won’t cut it. The issue is simple. Without a thermal break, metal frames and lids create cold bridges. These cold bridges then cause:

Heat loss – Warm air escapes, particularly in winter, which reduces the overall efficiency of your insulation strategy.

Condensation risk – Cold surfaces can encourage internal moisture to gather, potentially leading to damp or mould.

Disrupted U-value calculations – Even if most of the roof is high-performing, a single weak spot can bring the average down.

Thermally broken roof access hatches solve this by separating internal and external metal with a layer of insulation. That break in conductivity dramatically reduces heat transfer. In other words, the thermal envelope stays intact, even where access is needed.

Functionally, these hatches still do everything they’re supposed to. They open and close reliably. They provide a safe route to the roof for maintenance teams. Some can even be automated or integrated into larger systems. The key difference is they don’t drag down your U-values to do it.

Where U-Values Start to Suffer

A building’s thermal performance is often seen as the job of walls, roofs, and glazing. But it’s the junctions and small details that often cause the biggest issues. If you’re seeing a performance gap between the predicted energy model and the final test results, here’s where U-values typically drop:

- Uninsulated access points – Roof hatches, doors, and panels that haven’t been thermally upgraded.

- Poorly installed components – Gaps around hatches or poor seals let warm air leak out.

- Metal-to-metal contact – Direct connections between internal and external parts, especially steel or aluminium, create cold spots.

- Outdated specs – Using legacy products that were never designed with modern energy standards in mind.

The frustrating part is these aren’t always obvious during design. On paper, the building may look compliant. But once construction is complete, even one overlooked element can impact the final blower door test or EPC rating.

It’s Not Just About Insulation Depth

When thinking about thermal performance, many assume more insulation equals better results. And in some cases, that’s true. But insulation on its own isn’t enough if there are breaks in the continuity. Thermal bridging often bypasses insulation entirely, and that’s where low-performing access points become an issue.

Thermally broken systems don’t rely solely on depth. Instead, they work by stopping the route that heat would normally travel along. Think of it as blocking a shortcut. Heat can no longer pass freely from inside to outside. That’s how U-values are maintained without needing to bulk up surrounding materials or make awkward design sacrifices.

How to Ensure Performance Without Downgrading Access

Getting the best of both worlds is possible, but it does require early consideration. Waiting until late in the project to address roof hatches or access points can limit your options. To keep things simple, focus on a few core priorities from the start:

1. Look for full thermal separation

Partial improvements don’t solve the problem. The best-performing hatches have complete separation between the internal and external metal, often using a high-performance insulator within the frame and lid.

2. Prioritise air tightness

Even if the hatch itself is thermally efficient, poor sealing will still cause problems. Ensure compression seals or gaskets are included, and that they maintain contact even under pressure or wind load.

3. Think about operability

Just because something is thermally efficient doesn’t mean it should be difficult to use. Check how the hatch opens, how secure it is, and what options exist for safe and easy operation. Manual and powered options may suit different use cases.

4. Review compatibility with your roof build-up

Not every access hatch fits every type of roof. Make sure the thermal break doesn’t conflict with your membrane, insulation thickness, or drainage design. The goal is integration, not just compliance.

5. Understand the testing standards

Products should be backed up by verified thermal data. That means tested U-values under standard conditions, not estimated figures. If needed, ask for supporting documentation from the supplier.

Smart Design, Smarter Performance

Thermal efficiency and building access do not need to be enemies. With the right approach, they actually work together. When thermally broken roof hatches are included early in the process, they support the overall design goals instead of working against them.

That’s why performance-led specification matters. It’s not about adding expensive or specialist items late in the build. It’s about making smarter choices at the right time, so the final result lives up to its thermal promise without limiting how the space functions.

If the goal is long-term efficiency and usability, then ignoring roof access is no longer an option.

Building Performance Doesn’t End at the Wall

Every part of a building’s envelope contributes to thermal success, not just the obvious ones. Access hatches, doors, and service penetrations often get less attention, but they’re essential parts of the energy picture.

Maintaining low U-values isn’t just about ticking boxes. It’s about keeping comfort levels high, preventing unnecessary heat loss, and ensuring that your design decisions hold up in real-world use. Function should never be sacrificed in the process. And with thermally broken access solutions, it doesn’t have to be.