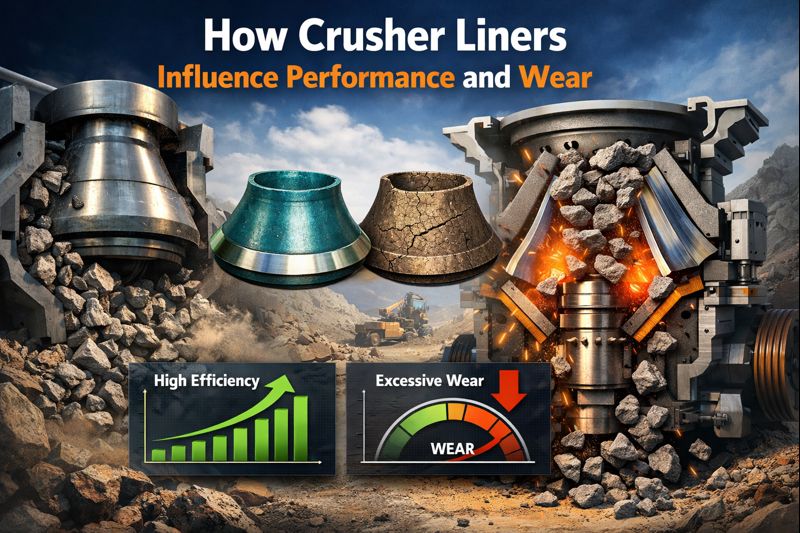

How Crusher Liners Influence Performance and Wear

The efficiency of any crushing operation, whether processing ore, aggregate, or recycled concrete, is fundamentally dependent on the consistent, reliable performance of the crushing chamber. Factors like particle shape, throughput, and energy consumption are all meticulously managed to maximize output and minimize cost.

At the heart of this process are the sacrificial wear parts: the liners. These components, which take the brunt of the destructive forces involved, are far more than simple protective shells. Their geometry, metallurgy, and condition critically dictate how material breaks and flows through the machine.

Ignoring the advanced engineering behind these components is a common operational oversight that leads to spiraling costs. Understanding the strategic role of high-quality crusher liners is essential for optimizing both crushing efficiency and the longevity of the entire machine.

Table of Content

The Relationship Between Liner Design and Output

The profile of a crusher liner is not arbitrary; it is precisely engineered to control the crushing action and the flow dynamics of the material. Different liner designs, such as those with steeper angles or deeper corrugated patterns, are used to achieve specific product shapes and sizes.

For instance, a profile designed to produce a finer, more cubical product will necessitate a more aggressive crushing action, often increasing the amount of wear on the liners. Conversely, a profile optimized for throughput may produce a more slabby, less desirable material shape.

Optimal liner design aims to strike a balance: maximizing the contact area to ensure effective breakage while maintaining an even wear profile. A poorly designed or incorrect liner can lead to ‘pegging’ (material jamming) or excessive slip, which wastes energy and reduces output quality.

Wear Patterns and Material Selection

Crusher liners fail due to two primary forces: abrasion, caused by material rubbing against the surface, and impact, caused by the heavy forces of material striking the liner. The dominant wear mechanism dictates the required liner metallurgy.

In high-impact applications, such as primary crushing of hard rock, manganese steel is often utilized for its ability to work-harden under continuous stress. For highly abrasive applications, like processing sand or high-silica rock, chrome white iron or specialized alloys are necessary to resist grinding wear.

Understanding the specific failure mode—is the liner being chipped away or polished smooth?—is vital for future material selection. Using the wrong alloy for the dominant wear pattern can result in the component being worn out in a fraction of its expected service life.

Impact on Throughput and Energy Use

As liners begin to wear, the gap and profile of the crushing chamber change. This alteration directly affects the throughput efficiency, requiring the operator to potentially slow the feed rate or adjust settings to prevent choking and ensure the material is processed correctly.

Severe wear also leads to a significant increase in energy consumption per ton of processed material. The machine must work harder, or less efficiently, to achieve the same result because the worn liner profile is no longer optimizing the transfer of crushing force.

The operational costs associated with prolonged use of worn liners—higher energy bills, reduced tonnage per hour, and lower product quality—quickly eclipse the cost of replacement parts. Maintaining optimal liner thickness and profile is a critical lever for cost control.

Maintenance Cycles and Replacement Timing

Proactive management of liner wear is a key component of effective maintenance strategy, shifting away from reactive replacement. Relying on visual inspection alone is insufficient; accurate measurement and data tracking are required to determine the optimal change-out point.

Changing liners too early wastes the remaining service life of a costly part. Changing them too late risks structural damage to the crusher frame itself and ensures substantial loss of productivity due to poor crushing efficiency and eventual catastrophic failure.

Therefore, many operations utilize advanced monitoring tools, such as ultrasonic thickness measurements or sensor data, to predict the ideal maintenance window. This precision allows the replacement cycle to be scheduled during planned downtime, minimizing operational disruption.

Optimizing Liners for Specific Applications

No single liner type is universally perfect; the optimal solution is always tailored to the specific application parameters. This involves considering the material’s feed size, hardness, abrasiveness, and the desired final product gradation.

For specialized aggregate production, for instance, a cone crusher liner may be designed to increase the amount of inter-particle crushing to improve cubical shape, whereas an operation focused solely on high throughput might select a more open, less aggressive design.

Working with an experienced supplier who can provide customized profiles and metallurgy based on detailed operational analysis is crucial. This collaborative approach ensures that the liners are not just protecting the machine, but actively enhancing its crushing potential for maximum return on investment.